Feed pellet machine for animal

Commercial Pellet Mill Wet and Dry Feed Pellet Machine Pellet Press Animal Feed Processor Farming Feed Machine 220V/380V

Free shipping on orders over $50!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

描述

Product name: Poultry animal cattle food fish dog pellet feed making diesel mill machine for sale

Material: Copper core motor,Stainless steel

Applicable types: Poultry, livestock, pets;

Feed processing type: Soybean meal, corn, grain, straw, wheat bran, etc .;

The product adopts a new type of double universal joint drive shaft, stable operation, low noise, automatic leveling, low transmission loss, sufficient power, no jamming, and more power saving!

Product Features:

-1. Coupling operation;

-2. High efficiency;

-3. Strong and wear-resistant;

-4. Durable;

-5. Precision machining;

-6. Copper core motor.

Product advantages:

-1. Extensive processing feed

Particle length can be adjusted, thickness can be selected;

-2. Upgrade grinding wheel

High-quality Ming Manganese steel material for longer service life;

-3. Stable and durable

Made of stainless steel, after high temperature hardening, it is more durable than ordinary steel;

-4. Newly upgraded coupling operation

Less transmission ratio loss and less loss;

-5. Nylon pulley

Will not damage and strong load;

-6. Bright blue body

After six baking processes;

-7. Increase the outlet

There are baffles on both sides to prevent the feed from falling;

-8. Widen and increase the inlet

It is convenient to put the feed ingredients that need to be made into the feed port;

Pellet mill in good price details:

This small home use pellet mill in good price is output from 50kg to 500kg per hour, it is fit for the home use or the small farm or the small factory. It is mainly fit for make all kinds of feed pellets, such as the chicken feed pellet, sinking fish feed pellets, dug pellets and etc. the working principle is the flat die fixed but the flat die rotary. when the flat die rotary, drves the rollers rotary.

Precautions:

1. When using, pay attention that there should be no hard foreign objects such as stones and iron blocks in the raw materials.

2. During granulation, it is strictly forbidden that the pressure roller and the template contact idling, and the continuous feeding can not be too fast or too slow without interruption. At the same time, lock the pressure roller shaft nut to avoid loosening and damaging the keyway of the spindle.

3. If there is no granulation and no discharge, the template should be removed, after opening the holes one by one, some fiber feed can be added appropriately to restart the granulation.

4. Always check the tightness of the screws on each part of the machine. If there is oil leakage in the gearbox, replace the oil seal in time, and whether the bearings in the ginger tea machine head are short of oil.

5. When the pellet machine is working, do not reach into the feeding port by hand. If necessary, you can use wooden sticks to help feed.

6. Before the machine is turned on, you need to add a little less material, and then leave a little private chat in the machine when it is turned on or off to prevent the machine roller and the grinding disc from contacting idling,

7. If the machine is stuck during working, it should stop immediately, press the pressure roller until the bolt is loose, and then restart it.

8. Every time the work is completed, the adjusting pressure roller bolts must be loosened.

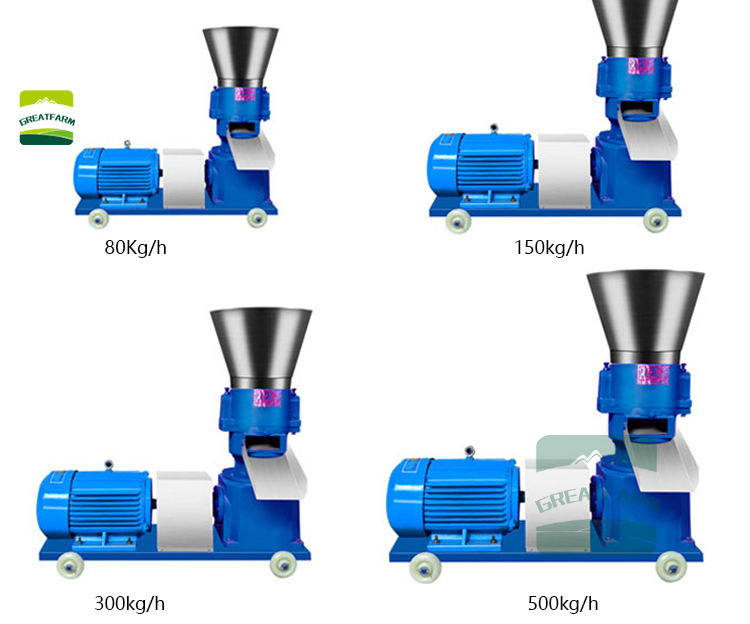

| Model | Capacity(KG/H) | Voltage(V) | Power(KW) | Weight(KG) | Size(CM) |

| 125 | 80 | 220/380 | 4 | 75 | 75*32*70 |

| 150 | 150 | 220/380 | 4 | 85 | 78*30*77 |

| 160 | 200 | 220/380 | 4.5 | 90 | 82*33*90 |

| 180 | 300 | 220/380 | 5.5 | 140 | 100*43*90 |

| 210 | 400 | 380 | 7.5 | 175 | 100*43*95 |

| 260 | 500 | 380 | 15 | 290 | 126*43*115 |

| 300 | 800 | 380 | 22 | 360 | 138*55*125 |

| 400 | 1200 | 380 | 30 | 750 | 160*80*170 |

Multi-scenario combined use, low cost processing and breeding, suitable for feed factories, ranches, farms, zoos, fish ponds, poultry feeding, etc

-1. Discharge funnel; -2. Length adjustment;

-1. Discharge funnel; -2. Length adjustment;

-3. Widen the discharge opening; -4. Fuel switch;

-5. Nylon casters; -6. Copper core motor;

-7. Couplings; -8. Final shaft adjustment machine.

-There are a total of four models of capacity machines: 80kg/150kg/300 kg/ 500kg;

-If you need more capacity machines, please contact customer service to customize.

-Copper core motor, High power, strong power, fast heat dissipation;

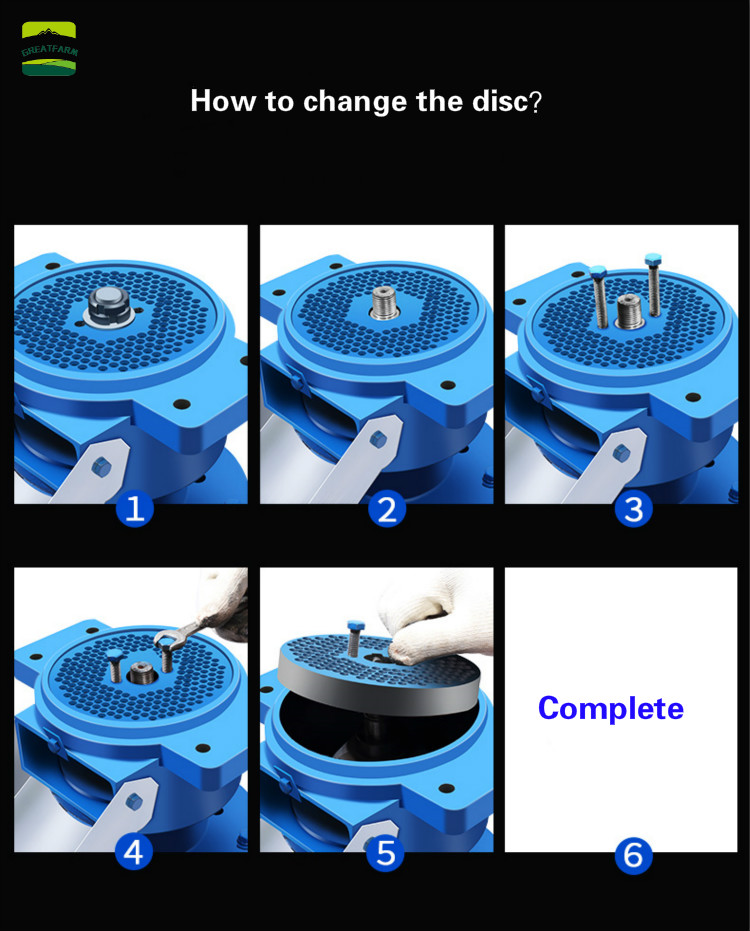

-It only takes 5 steps to easily replace different types of grinding discs.

-Grinding plate aperture display.

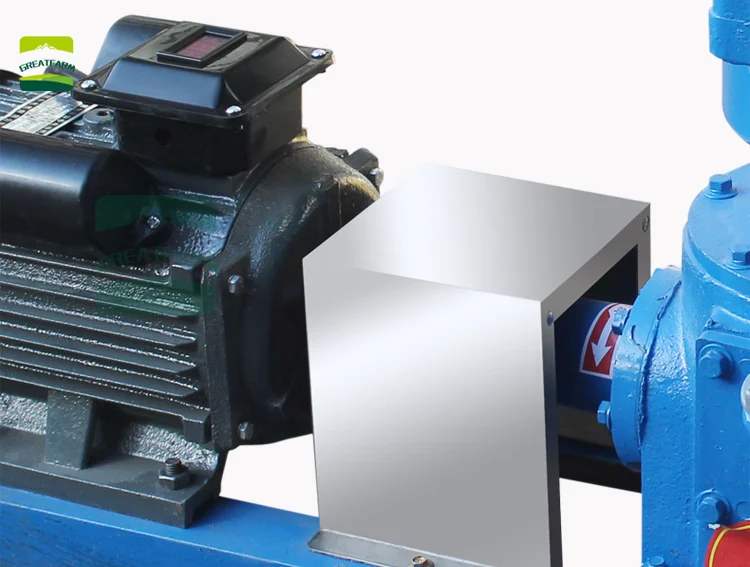

-Upgraded coupling, made of stainless steel, stable and durable.

-Product detail presentation.

评价

目前还没有评价